The Role of Free Length in Torsion Spring Angular Rotation

Free Length and Free Angle The ABCs of Spring Design Know spring back qualities. Free length is the unloaded length of the spring when there is no load applied to it. That length is crucial for getting the torsion spring to work well.

This is a topic to consider when designing a torsion spring: how free length influences the winding of torsion springs. The amount of available turn of a torsion spring is influenced by the free length. A longer spring will generally go through more turns than a shorter spring.

Advantages

The relationship between length and how well torsion springs function can be a bit tricky, but a useful thing to consider. The free length of a torsion spring determines stiffness or flexibility, which can be used to decide how the spring will behave in certain situations. By coming up with the optimal free length for a torsion spring, engineers can ensure a spring will work well for the context in which it needs to function.

Optimal diameter Having mentioned optimal free length and wire diameter, free length is a compromise since the free length is directly related to relaxation and stress at each applied stress level. Engineers should consider what the spring will be used for, such as how much it will carry and the way in which it will move, in order to determine its best free length. Engineers can cause a spring to function well and last a long time by setting its free length.

Benefits

When working on the free length of a torsion spring, consider what it is made of, what it will be used for and how well you need it to function. Various materials respond differently when pushed or pulled, so it is important to select the right material for the task. Additionally, factors such as heat, resistance to rust and how long the spring will need to last are considered when creating a torsion spring.

Summary

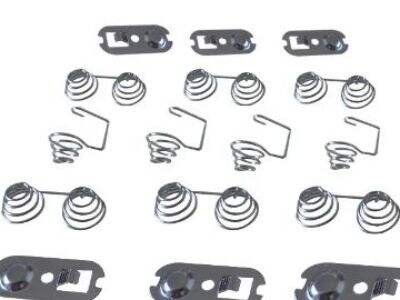

The free length of a spring tension clips determines how well a torsion spring will work. By understanding how free length influences how the spring coils as well as it can, engineers can ensure their springs serve the requirements of their jobs and perform at an optimal level throughout their lifespan. By considering what materials go into the spring, how the spring will be used and perform, engineers can design torsion springs that are dependable and work well in many different applications.