When manufacturing precision stamping parts, it is very important to make it perfect. That means paying attention to every little detail to make sure the end result is perfect. HENP tries to achieve the highest standards and accuracy of these parts. Here’s more about why precision in stamping parts is so critical and how it impacts the manufacturing process.

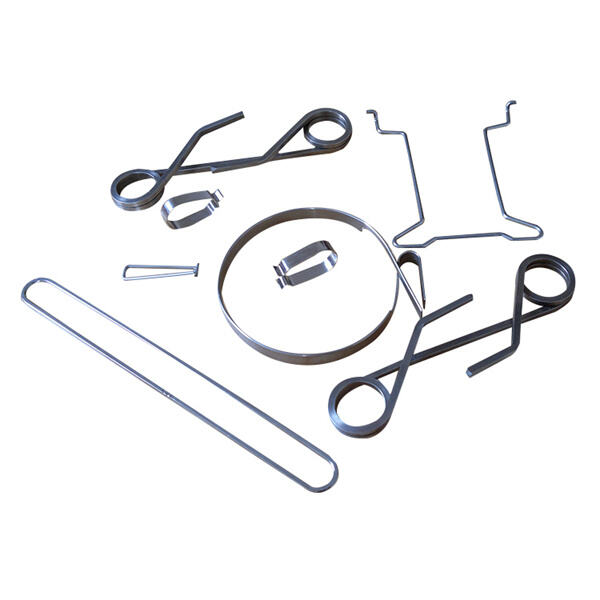

Accuracy in the forming of the parts is essential. One error, no matter how small, and the end product can have big issues. That is why HENP rigorously ensures that every part is perfectly constructed. Definition of Precision Stamping Precision stamping is a metalworking process using special tools, the so-called metal dies, and machines to process metal sheet material to produce shapes and forms. Such meticulous work ensures all components meeting high-standards.

Ms. Torske knows that creating perfect stainless steel spring clips is not simple to do. It requires a crew of talented workers and engineers who understand a lot about the stamping process. HENP employs an experienced staff of professionals who aim to offer you precision and dependable parts. With new technology and clever techniques they are able to manufacture high quality stamping parts while the customer is satisfied.

The significance of precision stamping on enhancing the quality of the product The importance of precision stamping of manufacturing industry 1. For companies such as HENP, precision stamping is a critical means of producing components that can be strong, efficient and cost-effective. With precise measurements and tight tolerances, they can ensure each piece works well and fits perfectly within the final product. This precision also contributes to a better quality product and eliminates possible discrepancies.

There are a lot of production steps for precision stamping parts. The design team first draws up elaborate plans for each part. Next, the stamping process begins with tough machines that cut, bend, and mold the steel sheets. The parts are then stamped and put through tough quality tests in order to meet HENP’s strict quality policies. This delicate process requires precision and fine attention to detail at every turn.

There are many advantages to using precision stamping for manufacturing. Companies are more efficient, there is less waste, and they are more productive by investing in a quality stamping part. HENP understands the significance of precision stamping and its contribution to manufacturing overall. That is why they are committed to the highest-quality stamping parts on the market, to ensure their customers are successful in today’s fast-paced and competitive market.